Authors: Kolchanov D.S., Ilya Mitrofanov, Artem Kim, Yury Koshtyal, Aleksander Rumyantsev, Sergeeva E. Yu., Vinogradov A.V., Anatoly Popovich, Maxim Yu. Maximov

Abstract

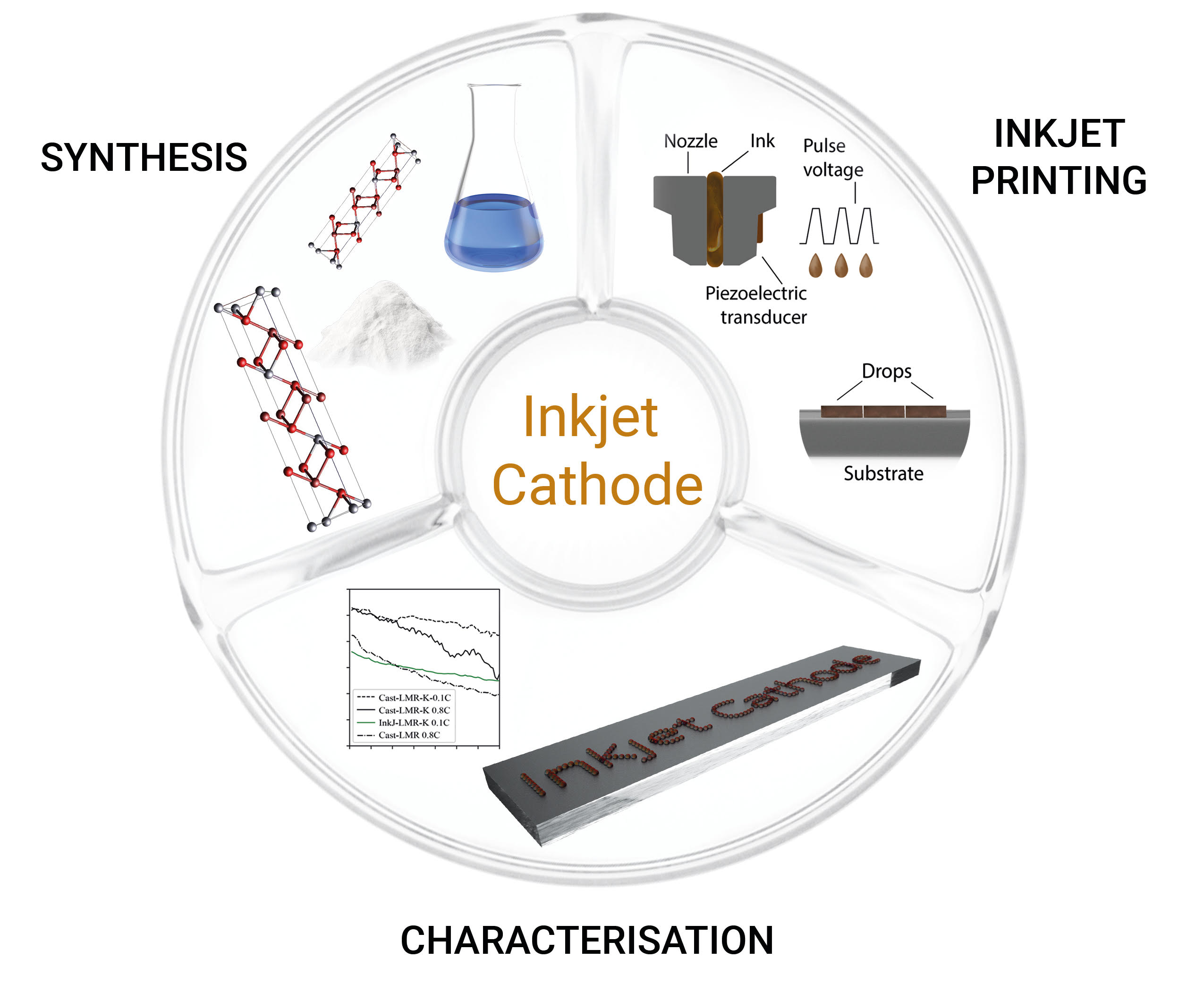

The observed downsizing tendency of microelectronic devices leads to a higher demand in new types of miniaturized energy sources. Thin‐film Li‐ion batteries (LiBs) are promising candidates to fulfil this function. New materials and technologies should be investigated for customized production of miniaturized, high‐efficient solid‐state batteries. In this work, we consider inkjet printing technology as a promising one for the fabrication of LiBs. The modification of crystalline lattice of Li‐rich cathode material by aluminium, sodium, and potassium and their influence on power efficiency were studied in detail. Lithium‐manganese‐rich compounds were chosen as the most suitable composition of an active component for LiBs fabrication. The stable aqueous colloidal ink composition was synthesized and its rheological parameters were optimized for inkjet printing in terms of viscosity, surface tension, and contact angle. We report on protocols for inkjet printing for fabrication of thin‐film cathodes with thickness of less than 10 µm. The good correlation of electrochemical properties such as average voltage, capacity and energy between inkjet printed and conventionally fabricated electrodes confirmed the feasibility of the suggested technological approach and selected cathode material composition.

DOI: https://doi.org/10.1002/ente.201901086

Read Full: https://onlinelibrary.wiley.com/doi/epdf/10.1002/ente.201901086